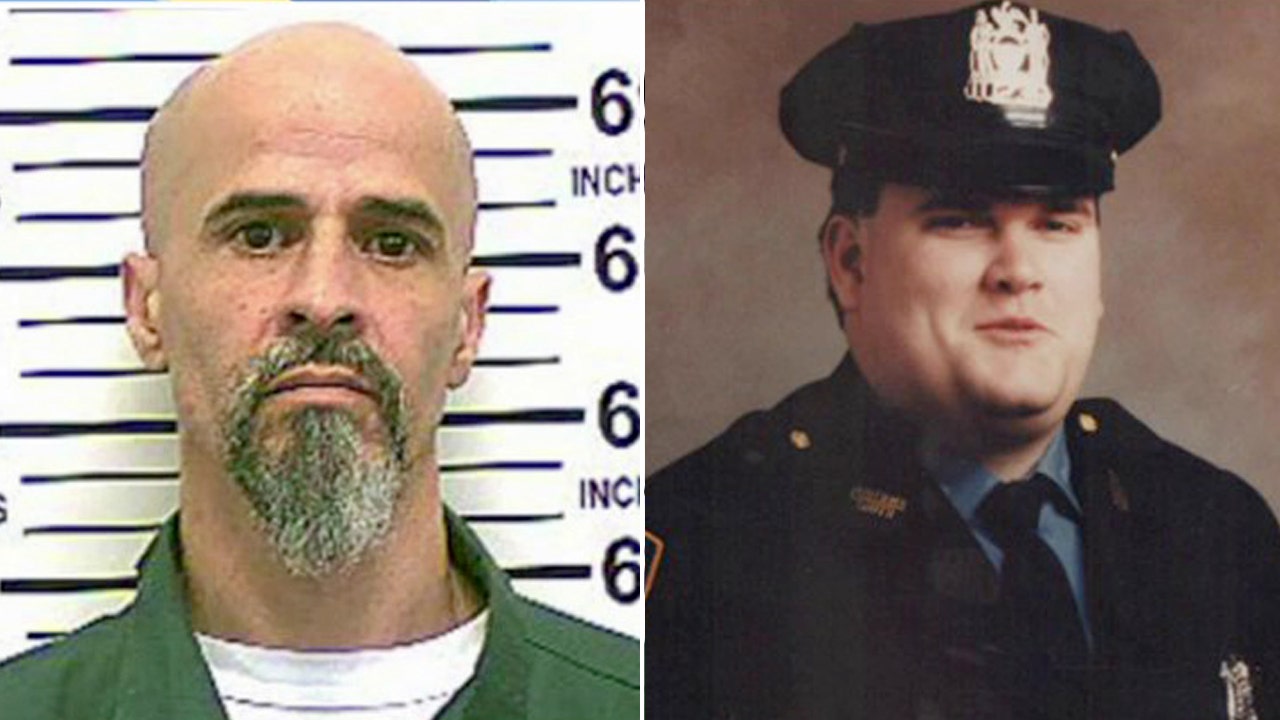

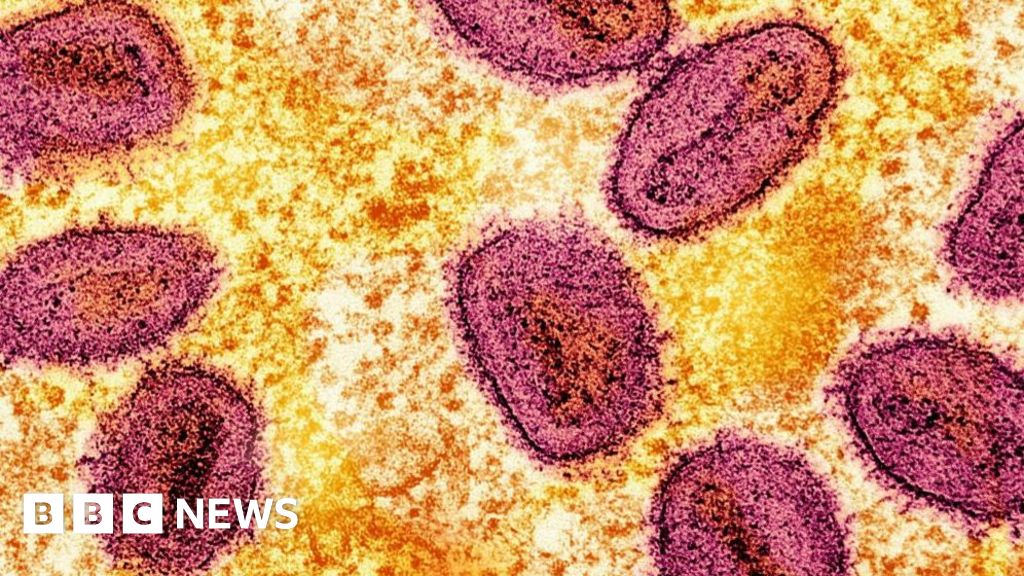

Dove Ice Cream Bars are packaged at Mars’ factory in Burr Ridge, Illinois.

Source: Mars

Candy giant Mars is trying to make a name for itself in a new category: ice cream.

The family-owned company aims for its ice cream business to reach $1 billion in sales worldwide by 2030. In May, Mars tapped executive Anton Vincent to lead its global ice cream business, adding to his existing role as president of Mars Wrigley North America.

Mars faces tough competition to achieve its ambition in the U.S., but the company has been investing into the business. It has spent $50 million upgrading its Burr Ridge, Illinois, ice cream factory and earmarked an additional $20 million for the facility that it hasn’t spent yet.

Mars has also been expanding its portfolio, rolling out new flavors such as M&M’s Cookies and Cream Ice Cream Cookie Sandwiches and Twix Cookie Dough Ice Cream. It used its $5 billion acquisition of Kind North America, best known for its nut bars, to push into plant-based ice cream substitutes.

While summer is still the biggest season for ice cream sales, Mars is also trying to boost business in the fall and winter through a partnership between the National Football League and its Snickers Ice Cream Bar.

Mars aims to grow its share of the ice cream market as part of a broad-based business. Outside of candy and ice cream, Mars also owns a large pet care segment and other food brands, including Combos Stuffed Snacks and Ben’s Original rice.

The bet on ice cream has paid off for the company. In the last five years, Mars’ global ice cream sales have risen 42%. The Dove Ice Cream brand alone grew 12% last year. As the segment grows, the U.S. accounts for more than half the company’s ice cream business.

As Mars injects resources into the ice cream business, the company will find out if its familiar brands are enough to carry it to its ambitious $1 billion sales target.

Mars’ ice cream goals hinge on the old and the new

Mars entered the ice cream category in 1986 when it bought Dove, then known just for its ice cream bars before the candy company expanded it into chocolate. Three years later, Mars introduced the Snickers Ice Cream Bar, now the top seller in its portfolio, followed by M&M’s Ice Cream Cookie Sandwiches.

“We don’t have the biggest ice cream brands, but we do believe we have the biggest brands in ice cream,” Shaf Lalani, the U.S. head of Mars Ice Cream, told CNBC.

Today, Mars ranks among the top 10 U.S. ice cream makers by retail sales, according to Euromonitor International data. But it is far outstripped by Haagen-Dazs owner General Mills; Ben & Jerry’s parent Unilever; and Blue Bell Creameries, which is privately owned.

“Mars Inc. ice cream brands face hefty competition, being ranks away from the leading spot in the U.S. ice cream market,” said Carl Quash, Euromonitor’s head of food and nutrition research.

As it tries to make up that ground, Mars’ primary strategy to grow its ice cream sales focuses on reversing what it did with Dove: taking other candy brands and turning them into frozen treats.

“There’s about a 64% crossover rate to people that buy our confectionary products and participate in our brands, which has given us a lot of confidence that we have the right to win,” Lalani said.

Outside of Snickers and M&M’s, Mars’ other candy brands show promise in their transition over to ice cream. Twix Ice Cream is the fastest-growing product in the company’s ice cream portfolio. Lalani thinks the frozen version of the Milky Way candy bar — known as the Mars bar outside the U.S. — has the potential to be its next big hit.

While Lalani said Mars’ existing portfolio has plenty of runway, not all of Mars Ice Cream’s growth will be organic. Acquisitions will also help fuel sales and bring new customers.

For example, Kind’s frozen treats entered Whole Foods a few months ago, adding a new retail chain to Mars’ frozen footprint.

In December, Mars announced it was buying Tru Fru, a startup that makes frozen and freeze-dried chocolate-covered fruit. Financial terms of the deal were not disclosed.

Inside the ice cream factory

Dove Bars are dipped in chocolate at the factory.

Source: Mars

Nearly four decades ago, when Mars bought Dove, it also purchased the brand’s manufacturing facility in Burr Ridge, Illinois. These days, the factory is responsible for making all the ice cream the company sells in the U.S., which accounts for 55% of its demand worldwide.

As sales have accelerated, the company has had to invest in the sprawling facility to add capacity and the capability to make new products, such as Kind’s frozen treats studded with nuts. The factory has distinct lines dedicated to the types of products Mars makes: sandwiches, bars and sticks.

Mars’ manufacturing process is largely automated, and workers stand by to monitor the machines. Many of the ingredients come from elsewhere — the ice cream mix and M&M cookies from regional suppliers, the peanuts from Mars’ roasting facility — and they all come together in the Burr Ridge factory.

But it’s a delicate process, requiring precision to balance consistency, quality and the temperature demands of ice cream.

For example, the Snickers Ice Cream Bars feature a layer of ice cream, the candy’s signature peanuts and caramel and a chocolate exterior. Inside the chilly factory, the chocolate has to stay warm enough to melt on top of the ice cream bar, which the conveyor belt then quickly moves through a freezing tunnel, so the ice cream doesn’t melt.

From there, the Snickers Ice Cream Bars move past sensors that detect production mistakes, such as being too large or too small. The Snickers’ peanuts are often the culprit.

The machine swiftly pushes the rejects aside, joining a crowd of fellow outcasts in melting slowly. The floors of the production line are dusted with the chocolate ashes of those that fell short of Mars’ standards. To keep the ice cream bars from melting, the conveyor belt has to move quickly, leaving no time to correct the misfits.

But those that make the cut move down to be wrapped in Snickers’ packaging. Mechanical arms use small vacuums to pick up the Snickers bars without crushing them and place them into wrappers, which are then put into individual boxes and placed in cartons.

New products also bring new manufacturing challenges. For example, Kind’s frozen bars are meant to taste the same with every bite taken, but the chunks of nuts presented difficulties meeting that level of consistency, according to Romain Lepicard, head of the Mars Ice Cream research and development team.

The $50 million Mars spent already largely went toward upgrading the line dedicated to its ice cream bars, which can churn out several hundred thousand Snickers Ice Cream Bars per day. The investment also went toward some other tech upgrades, such as digital screens that will help the facility go paper free.

Mars will spend the additional $20 million investment on further boosting how many ice cream bars the factory can make. The company plans to invest in equipment that will help it make more of the components for the Snickers Ice Cream Bars, such as caramel, plus other upgrades to capacity for the manufacturing line.